Company news

Breaking through the precious metal casting process --3D printing

Breaking through the precious metal casting process - Yihui takes you to understand how 3D printing reshapes the precious metal casting process

In the casting industry, especially in the field of precious metal casting such as gold, silver coins, and jewelry, "insufficient precision, low efficiency, and high cost" have always been the three core pain points that plague practitioners. The traditional mold making process not only requires several days or even weeks to produce wax molds, but also tends to encounter problems such as blurred details and low product qualification rates when facing complex structures such as high relief and filigree; In mass production, the waste of supporting materials and high polishing costs in the later stage have caused many foundries to fall into the dilemma of "unable to keep up with production capacity and compressed profits".

Nowadays, with the iterative upgrading of 3D printing technology, this situation is being broken. A 3D printer specially developed for casting scenes, with ultra-high resolution, efficient molding, and scene adaptation capabilities, has become a "breakthrough tool" in the precious metal casting industry - from wax printing to direct casting, from precision control to cost optimization, it comprehensively solves the shortcomings of traditional processes and brings a new path of digital transformation to foundries.

01. "Three Difficulties" of Traditional Casting Technology

Directly targeting industry characteristics

Precious Metal Casting: Bottlenecks of Accuracy, Efficiency, and Cost

Traditional casting techniques face three core constraints of precision, efficiency, and cost in the fine processing of precious metals. The contradiction between their technical limitations and the demand for high-end customization and large-scale production is becoming increasingly

prominent.Accuracy bottleneck: Fine structures such as silver coin reliefs and jewelry filaments require micrometer level wax mold accuracy, which is difficult to achieve through traditional manual/mechanical molding. Mold wear during mass production can amplify errors, leading to high scrap rates;

Shortcomings in efficiency: A set of wax molds needs to go through design, mold making, and mold repair processes, with a sampling cycle of up to 3-7 days. Customized orders are prone to missing business opportunities, and mold replacement and debugging during mass production also limit production capacity;

High cost: The waste rate of traditional process support materials exceeds 50%, and the cost of later polishing accounts for 15% -20% of the total cost. Material loss and excess processes directly compress profit margins.

02. 3D printing solves casting problems

Yihui 3D printer

Empowering high-precision intelligent manufacturing tools in multiple fields

At present, with the increasing demand for precision manufacturing in fields such as precious metal processing, medical care, and industrial design, Yihui's 3D printer series relies on its independently developed core technology to solve the pain points of jewelry and precision cultural and creative casting with upgraded DLP light curing technology. It integrates the advantages of low shrinkage of special wax materials and high-precision of resins, and achieves "precision saving, high efficiency, and low loss" upgrades with dual zone oxygen supply, imported high-definition modules, and intelligent adaptation platforms, adapting to the mass production of complex jewelry and micro carved crafts.

14K/16K LCD 3D printer

In response to the pain points of traditional craftsmanship, the 14K/16K printer, starting from the three dimensions of "precision, efficiency, and cost", creates a professional solution suitable for precious metal casting scenarios through customized technology design:

Intelligent operation and maintenance+ultimate precision

14K/16K ultra clear accuracy: 10 * 12 μ m positioning+0.015mm printing accuracy, restoring 0.08mm texture/0.12mm filament, 30000 hours of UV light source+99%+pass rate;

Efficient cost control: Speed increased by 2.5 times (1.5 seconds per layer), support material saved by 40%, 100 silver coin wax molds completed in 3 hours, cycle reduced by 65%;

Intelligent and easy to operate: 15.6-inch touch control+remote control, 1 hour to use, 2 minutes to clean the material tank, leak proof liquid+7 × 24-hour continuous operation.

PRO 3D printer

Breakthrough in both accuracy and efficiency

High precision: self-developed 4K imaging+light uniformity algorithm (light uniformity of 92%), repeatability accuracy of ± 0.05mm, adjustable layer thickness of 0.025-0.1mm; Point to point glue spraying, 1.5mm thin-walled molding, AI calibration, batch consistency increased by 35%+, with a pass rate exceeding the industry.

Modelless: "Selective bonding" technology, CAD direct conversion sand mold saves 10+processes; Small batch/trial production cycle of 15-45 days → 3-10 days (R&D by car companies increased by 30%), no mold cost reduction of 40% -60%, and waste sand recovery rate of over 90%.

Full compatibility: compatible with multiple substrates, supporting 50+industrial materials (aviation/automotive/nuclear power available); 2000 × 1200 × 800mm large size, 1.5-meter component formed in one go; 45 minute quick material change (only one-third of traditional).

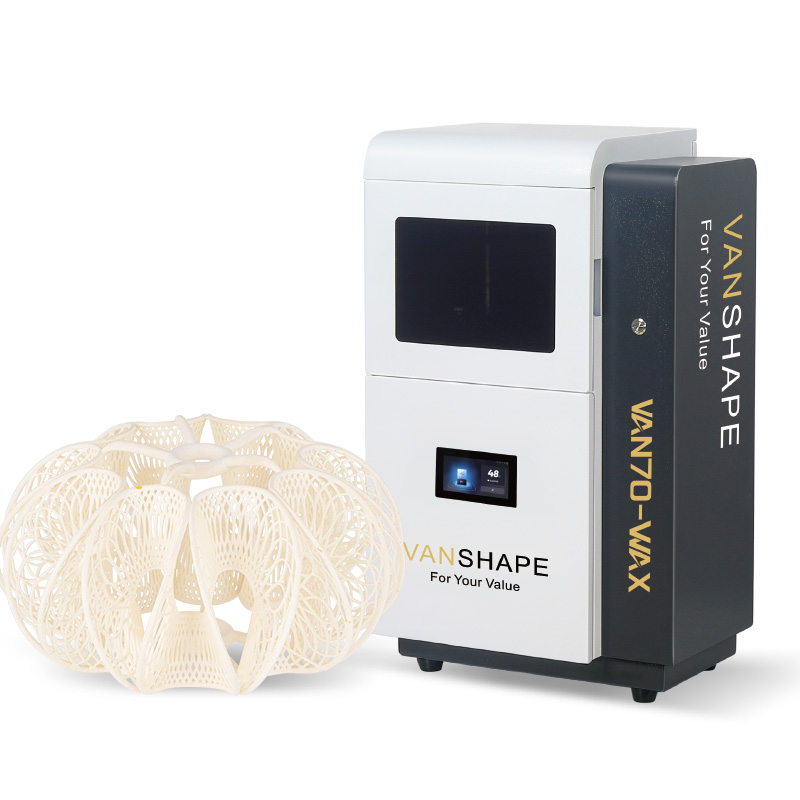

White wax 3D printer

Compatible with multiple materials and covering multiple fields

Precision configuration: American control chip+UV light source (lifespan>10 years), Japanese Z-axis guide rail+precision screw; 16K printing accuracy of 0.02mm, positioning of 14 * 19 μ m, adjustable layer thickness of 0.025-0.1mm; Some models have an XY axis of 50 μ m and a Z-axis movement of 0.003mm, and the finished product does not require polishing.

Process advantages: Omron oxygen supply system, starts after 5 minutes of oxygen supply, with a speed increase of 2 times and support of 2/3; High wax content white wax (low shrinkage, easy demolding), detachable material trough, easy maintenance.

Operation scenario: 14 inch screen+integrated computer, Chinese and English interface, offline printing (read JewelCAD/STL from USB drive); Compatible with white wax/resin, compatible with multiple substrates, covering jewelry/aerospace/medical, 16K supports cross-border.

In the future, with the further iteration of 3D printing technology and the continuous optimization of specialized resin materials and supporting processes, the integration of 3D printers and the casting industry will become deeper. We have reason to believe that such high-precision and cutting-edge equipment will drive the casting industry into a new era of "ultra-high precision, ultimate efficiency, and low cost".

Copyright © Guangzhou Vanshape Technology Co.,Ltd. 粤ICP备17100380号