Company news

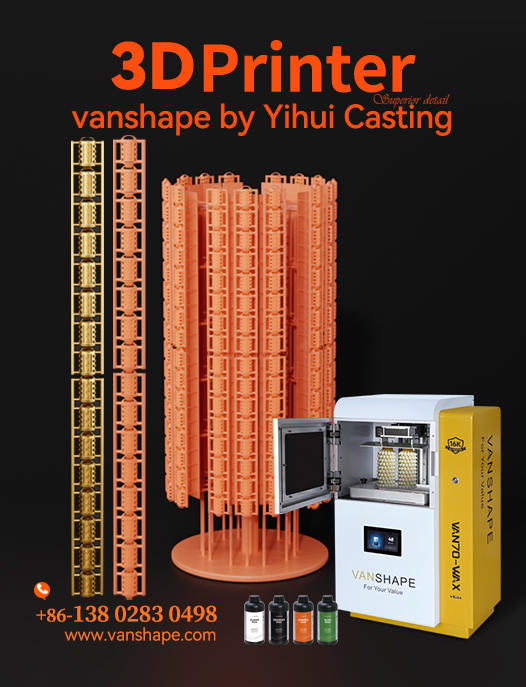

vanshape 16K 3D printer: revolutionizing jewelry design and casting

16K 3D printer: revolutionizing jewelry design and casting

In the field of high-end jewelry, precision, creative expression, and production efficiency are the three core factors for establishing a foothold in the market. The traditional wax carving and molding process is not only time-consuming and labor-intensive, but also difficult to break through the design limitations of complex structures - fine threads, micro inlaid slots, and personalized customized styles often rely on the manual skills of experienced craftsmen, and precision deviations are prone to occur in mass production. The Yihui 16K 3D printer breaks the industry bottleneck with Zhubao's exclusive DLP projection technology, seamlessly connecting digital design with physical craftsmanship, injecting new energy into jewelry 3D printing, and becoming a core production tool for global jewelry brands, foundries, and independent designers.

As a craftsmanship enterprise that has been deeply involved in the jewelry casting field for more than 20 years, Yihui has optimized the core parameters of its equipment in a targeted manner, enabling 16K resolution technology to accurately match the demanding needs of the jewelry industry. It has achieved triple breakthroughs in detail presentation, efficiency improvement, and cost control, redefining the digital production standards for jewelry.

16K resolution: Unlocking the upper limit of precision for jewelry 3D printing

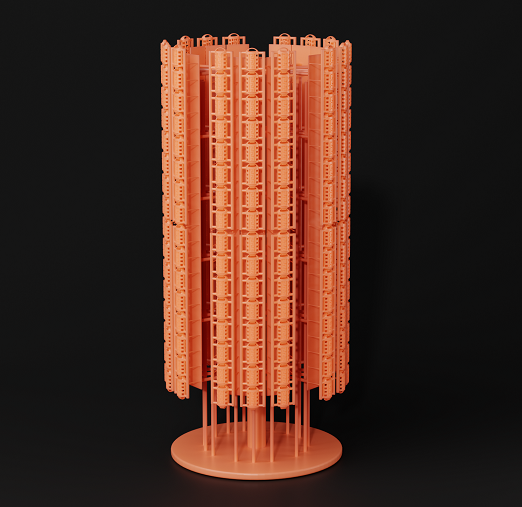

Delicacy of jewelry products is already established from the wax mold stage. Even a deviation of 0.1mm may cause misalignment of gemstone inlay, fracture of filament structure, and ultimately affect the value of the finished product. 16K 3D printer, with industry-leading parameter configuration, pushes wax mold accuracy to new heights and perfectly adapts to the core demands of jewelry production.

Ultimate precision performance: Supports 0.02mm layer thickness printing and 14 × 19 μ m positioning accuracy, which can accurately restore details that are difficult to achieve with traditional processes such as 0.2mm fine filaments and micro inlaid grooves. The wax mold surface has excellent smoothness, greatly reducing subsequent mold execution costs. This precision advantage has upgraded the 3D printing of filigree jewelry from a "technical attempt" to a "batch application".

Jewelry exclusive consumables adaptation: Compatible with white wax, high wax content resin (wax content 50% -80%), and 100% pure castable wax, the printed product achieves no residual combustion during wax loss casting process, eliminating casting defects such as burrs and burrs from the source, meeting the strict standards of jewelry wax loss casting.

Efficient mass production: Printing speed reaches 2-3 layers/second, and the molding size is 211.68 × 118.37 × 180mm. Within 4 hours, more than 20 ring wax molds can be printed in bulk, compressing the traditional "several day cycle" of wax carving to the hour level, significantly improving the delivery efficiency of small batch customization and popular reprints.

Vanshape Exclusive Advantage: Tailored for Global Jewelry Negotiations

Compared to general-purpose 3D printers, the core competitiveness of 16K devices lies in "deep adaptation to jewelry scenes", which fully meets the needs of global users from hardware to services:

Digital workflow: A minimalist path from design to finished product

The vanshape 16K 3D printer seamlessly integrates into modern jewelry production processes, greatly simplifying operational steps and reducing reliance on manual experience

1. Use CAD software to complete jewelry design (supporting STL/SLC format), optimize printing angles and support structures;

2. Install jewelry specific wax or high wax resin without complex calibration, and start the printing program;

3. Complete wax printing within a few hours, with complete preservation of precision and details;

4. Simple post-processing: IPA cleaning, UV curing, requiring only a small amount of support for removal due to precise design;

5. Enter the lost wax casting process, with no residual combustion to ensure the smoothness of the metal product and reduce the need for later polishing processes.

Empowered by technology, jointly building a new future for the jewelry industry

With 3D printing technology becoming the core driving force for innovation in the jewelry industry, the vanshape 16K 3D printer is not only a production tool, but also an important support for brands to break through development bottlenecks and build core competitiveness. Whether it is an independent designer pursuing the ultimate creativity or a large foundry emphasizing scale efficiency, they can use this equipment to find a balance between personalization and mass production, unlocking more possibilities for jewelry design and production.

Copyright © Guangzhou Vanshape Technology Co.,Ltd. 粤ICP备17100380号