Company news

Technology empowers creativity,Yihui 3D printers unlock diverse application scen

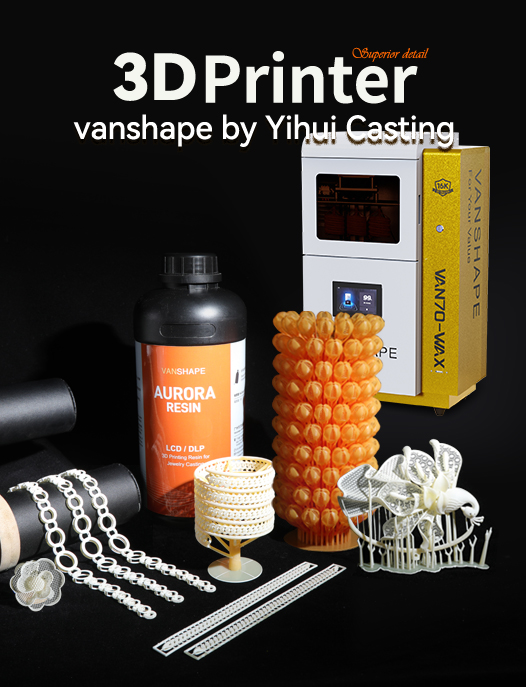

Under the wave of digital transformation in the global jewelry industry, Vanshape by Yihui Casting has launched a 16K jewelry 3D printer with deep industry expertise. With ultra-high definition accuracy, efficient production capacity, and wide adaptability, it has become a core hub connecting design creativity and mass production implementation. This device not only achieves industry breakthroughs in technical parameters, but also demonstrates strong strength in various scenarios such as high-end customization, brand mass production, and cultural and creative development, continuously injecting intelligent manufacturing momentum into global jewelry enterprises.

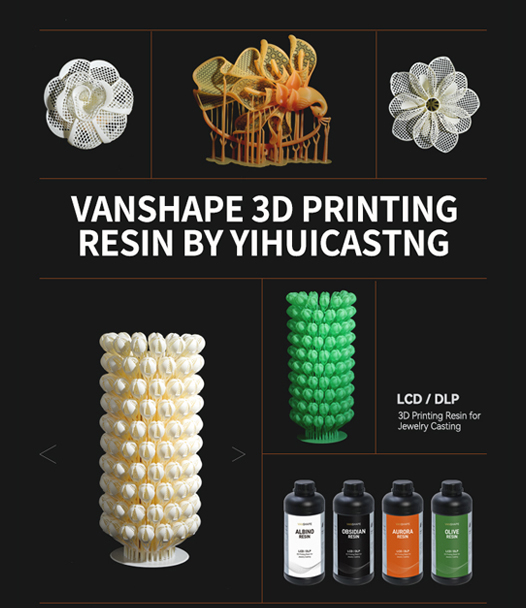

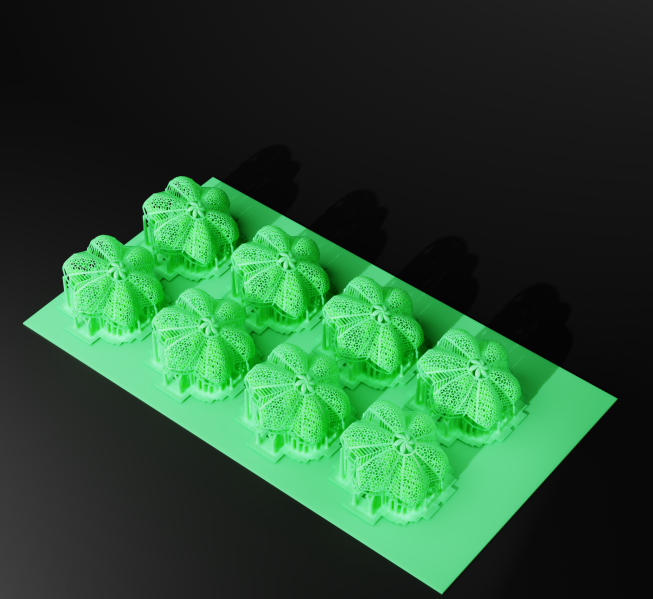

Vanshape by Yihui Casting 16K jewelry 3D printer is equipped with a new generation of DLP projection molding technology, achieving ultra-high printing accuracy of 0.02mm and precise positioning of 14 * 19 μ m, far exceeding the industry average level. It can perfectly replicate complex structures that are difficult to achieve with traditional processes such as snake scale texture, silk thread refinement, and dynamic joints. The equipment is equipped with an intelligent material adaptation system, compatible with various jewelry specific consumables such as white wax and low ash castable resin. The zero ash characteristic ensures flawless casting and reduces material waste by more than 30%, in line with the global trend of sustainable production. In terms of efficiency improvement, its layer thickness can be intelligently adjusted between 0.025-0.1mm, and the printing speed can reach 2-3 layers/second, shortening the traditional jewelry pattern making cycle from weeks to hours. The delivery cycle for small batch customized orders is compressed by more than 80%, significantly reducing the time cost of enterprises.

The rich application scenarios have become the core competitiveness of this device, fully covering the diverse production needs of the jewelry industry. In high-end customization scenarios, whether it is the exclusive relief of wedding rings, the precise replication of baby footprints commemorative gold jewelry, or the suspended interlocking design of art jewelry, the equipment can be quickly molded through digital modeling to help brands create high premium personalized products. It can meet the mass wax mold production of mainstream categories such as necklaces, rings, and brooches, and with fully automated process control, the casting success rate is over 99%. It has become the core production equipment of many light luxury jewelry brands in Europe and North America.

In the future, we will continue to deepen technological innovation, promote the integration of cutting-edge technologies such as 3D printing and AI design, further expand the application boundaries in fields such as smart jewelry and high-end watch accessories, and help the global jewelry industry achieve the development goal of "boundless creativity and high production efficiency".

Copyright © Guangzhou Vanshape Technology Co.,Ltd. 粤ICP备17100380号