Company news

Unleash the boundaries of creativity! 3D printers make jewelry design impossible

Jewelry design is a perfect fusion of art and craftsmanship, but the many limitations of traditional craftsmanship have turned countless excellent design ideas into mere talk on paper. Complex hollow structures, precise gap control, and three-dimensional dynamic modeling - these inspirations in the eyes of designers - cannot be achieved in traditional handmade production due to "difficulty in forming, insufficient strength, and distorted details". The arrival of 3D printing technology, with its core advantage of "unlimited geometric modeling," has completely unleashed the creative boundaries of jewelry designers, allowing boundless inspiration to be easily transformed into brilliant products, and promoting the jewelry design industry into a new era of "creativity is king".

Traditional craftsmanship: the "creative shackle" of jewelry design

Traditional jewelry processing relies on "subtractive shaping", just like shaping with rubber clay. When encountering complex hollow structures, spiral surfaces, micro bearings, and other designs, it is prone to collapse and deformation problems. For dynamic mechanical jewelry, such as rotatable planetary gear necklaces, deformable rings, etc., traditional craftsmanship requires disassembling components to make them separately and then assembling them. This not only makes it difficult to ensure accuracy, but also affects the overall aesthetics and stability. In terms of detail presentation, traditional manual carving is difficult to accurately control gaps below 0.1 millimeters, resulting in many intricate texture designs that can only be simplified. In addition, the high cost of trial and error in traditional craftsmanship, as well as the long production cycle and high cost of new design prototypes, have constrained the innovation enthusiasm of designers.

3D Printer: A Creative Artifact for Jewelry Designers

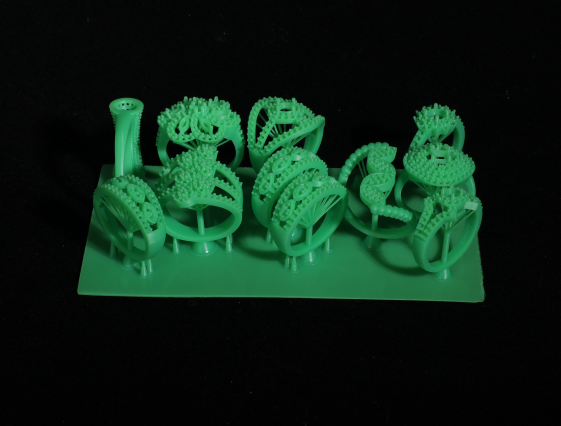

3D printing adopts the principle of "additive manufacturing", which constructs entities by stacking materials layer by layer, completely breaking the modeling limitations of traditional processes and making it easy to achieve any complex geometric structure. Whether it's honeycomb mesh earrings like miniature buildings or dynamic necklaces containing 12 miniature bearings, 3D printers can print them in one go without the need for subsequent assembly, ensuring structural accuracy and enhancing overall strength. The "dancing necklace" created by German designer Dirk utilizes 3D printing technology to achieve a planetary gear like free rotation effect, with a precise 0.1 millimeter gap reserved at each connection point, giving the cold metal a life rhythm.

The ultra-high precision of 3D printers provides designers with the ultimate space for expressing details. Using MicroPoint ™ The ultra-fine tip support structure allows 3D printers to achieve 0.05 millimeter level detail printing, which is three times thinner than a human hair. Whether it is the texture of stacked petals, the outline of miniature portraits, or the 0.2 millimeter diameter miniature claws, they can all be perfectly presented. At the same time, the rapid prototyping capability of 3D printing allows designers' creativity to quickly land, from digital modeling to prototype production in just a few tens of minutes, significantly reducing trial and error costs and allowing designers to boldly explore more innovative forms and material combinations.

Promoting design innovation: from "process oriented" to "creative oriented"

The popularization of 3D printing technology is driving the transformation of jewelry design from a "process oriented" to a "creative oriented" approach. In the past, designers had to adjust their design plans based on the limitations of traditional craftsmanship, forcing many ideas to compromise; Nowadays, designers can fully focus on creativity without considering process limitations, and explore multiple dimensions such as geometric aesthetics, dynamic structures, and emotional expression to their heart's content. The combination of 3D printing, 3D scanning, and AI design has revolutionized the design process - designers can obtain accurate data on natural elements and cultural symbols through 3D scanning, quickly generate thousands of design schemes with AI tools, and then quickly verify the effects through 3D printers.

In the context of the rise of China-Chic, 3D printing technology has become a bridge for the integration of traditional culture and modern design. Designers use digital modeling of intangible cultural heritage patterns, traditional totems, and other elements, and utilize 3D printing technology to achieve three-dimensional presentation. This not only preserves the essence of traditional culture, but also endows it with modern aesthetic value through innovative forms. This design that combines tradition and innovation is not only sought after by young consumers, but also promotes the inheritance and innovation of jewelry culture.

Leading Industry Aesthetics: 3D Printing Reshaps New Trends in Jewelry Design

3D printing technology is reshaping the aesthetic trend of the jewelry industry, with complex structures, dynamic modeling, and personalized expression becoming new design trends. From hollowed out earrings in the Starry Sky series to deformable mechanical rings, 3D printed jewelry has attracted the attention of a large number of young consumers with its unique design language and technological sense. More and more jewelry brands are setting up digital design studios, introducing 3D printing technology, and making design innovation their core competitiveness.

In the future, with the continuous upgrading of 3D printing technology and innovation in materials, jewelry design will usher in more possibilities. The combination of biosensors and jewelry, 3D printing will continue to promote the cross-border integration of jewelry design, making jewelry not only a decoration, but also a perfect carrier of technology and art.

Copyright © Guangzhou Vanshape Technology Co.,Ltd. 粤ICP备17100380号