Company news

Vanshape 3D printing technology leverages intelligent production of jewelry

Vanshape 3D printing technology leverages intelligent production of jewelry

In the dazzling field of jewelry manufacturing, precision, efficiency, and innovation are the core cornerstones of success. For decades, traditional casting techniques have always limited the creativity of designers, constrained production flexibility, and made it difficult to keep up with the global market's demand for customization, efficiency, and sustainability. Nowadays, vanshape by Yihui Casting, with advanced 3D printing technology and additive manufacturing as a breakthrough, reshapes the future of intelligent jewelry production and sets a new benchmark for quality and efficiency in the global jewelry industry.

As a pioneer in the field of casting technology, vanshape by Yihui Casting has long been committed to building a bridge between traditional craftsmanship and digital innovation. We are well aware of the many pain points of traditional jewelry casting, such as long mold making cycles, serious material waste, insufficient precision in complex styles, and unstable product quality. We continue to increase our research and development investment, integrate 3D printing technology into every aspect of jewelry production, create a fully digital and intelligent production process, and empower global jewelry brands, designers, and manufacturers.

The pain point of traditional jewelry casting: innovation is imperative

Traditional jewelry casting heavily relies on manual operation and outdated molding techniques, bringing many unavoidable challenges to modern production. Artificial wax injection often leads to uneven thickness, residual bubbles, and dimensional deviations in wax molds, requiring a large amount of manpower for later polishing and correction. This not only wastes time and labor costs, but also causes material loss. For styles with intricate cutouts and complex geometric shapes, traditional craftsmanship often falls short, limiting designers' creative expression and forcing brands to compromise on uniqueness.

In addition, traditional mold making is costly and time-consuming, and a single mold often takes several days or even weeks to complete. This inefficiency makes small batch customization and rapid market response almost impossible, putting jewelry brands at a disadvantage in the fast-paced global market. Meanwhile, the extensive control of metal temperature and pouring speed in traditional casting can easily lead to defects such as impurities and cracks inside jewelry, reducing the durability and value of the product.

Vanshape 3D printing 3D Printing: The Core Driver of Intelligent Jewelry Production

vanshape by Yihui Casting has developed 3D printing technology specifically for jewelry casting, which accurately addresses industry pain points and seamlessly integrates into the production process, achieving a comprehensive upgrade from design to finished products. Unlike traditional subtractive manufacturing, our 3D printing adopts an additive manufacturing mode, stacking materials layer by layer based on digital models to accurately create jewelry prototypes and wax molds, maximizing design freedom and improving production efficiency.

Yihui 3D printing technology empowers the core advantages of jewelry production

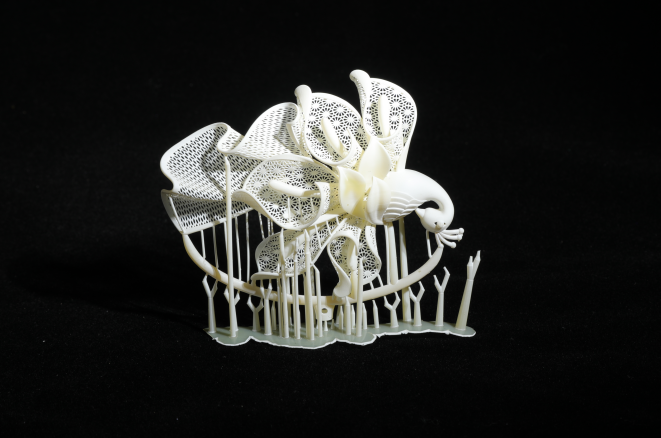

Ultimate design freedom: Yihui 3D printing technology breaks the limitations of traditional craftsmanship, allowing designers to freely express their creativity and create complex geometric shapes, fine hollow textures, and unique organic forms - whether it is replicating the delicate texture of natural insect wings or creating futuristic abstract structures, every detail and curve can be accurately presented in digital models, easily transforming creative ideas into touchable jewelry artworks.

Efficient production and shortened delivery cycle: After the 3D design is completed, the printer can produce 60-100 wax patterns in just 4 hours, shortening the entire production cycle from weeks to days. This enables jewelry brands to quickly respond to market trends, accelerate the pace of new product launches, and efficiently complete small batch and customized orders

Ultra high precision, stable and controllable quality: Yihui 3D printing has a precision of up to 0.01mm, which can perfectly restore every detail of jewelry and eliminate errors caused by manual operation. The 3D printing equipment is equipped with an intelligent control system, which strictly regulates the material dosage, temperature, and printing speed to ensure stable and unified product quality between batches, completely solving the quality fluctuation problem of traditional casting

Green and sustainable, outstanding cost-effectiveness: Yihui 3D printing reduces material waste through precise material control. Waste wax materials and metal scraps can be recycled and reused, which is in line with the global trend of low-carbon jewelry design. Recycling 1 gram of precious metal can reduce approximately 1.8kg of carbon emissions, helping jewelry brands achieve environmental goals while reducing production costs. For small batch customized orders, there is no need to invest high mold costs, and the cost advantage is more significant.

From digital design to intelligent casting: Yihui full process intelligent solution

vanshape by Yihui Casting not only provides 3D printing equipment, but also offers a full process intelligent production solution for jewelry manufacturers, seamlessly integrating 3D modeling, 3D printing, intelligent casting, and post-processing to build an integrated production process. Our professional team provides customized technical support to assist overseas clients in optimizing digital design files, debugging printing parameters, and quickly integrating 3D printing technology into existing production lines.

With the power of innovation, shape a new future for global jewelry manufacturing

With the increasing demand for customization, efficiency, and sustainability in the global jewelry market, 3D printing technology has become the key to unlocking intelligent jewelry production. Yihui Casting, with years of accumulated casting technology and profound insights into the jewelry industry, is committed to promoting the popularization of 3D printing technology in the jewelry manufacturing field and helping more overseas jewelry brands achieve digital and intelligent transformation.

Whether you are a small jewelry studio specializing in customized design or a large manufacturer pursuing large-scale production efficiency, Yihui Casting's 3D printing technology can provide you with tailored solutions to meet diverse needs. We adhere to the concept of "technology empowers craftsmanship, innovation leads the industry" and are committed to becoming a reliable partner for global jewelry brands in the field of intelligent production.

Gain a deeper understanding of our 3D printing jewelry casting solution and join hands to unlock infinite possibilities for intelligent jewelry production!

Copyright © Guangzhou Vanshape Technology Co.,Ltd. 粤ICP备17100380号